The 3-Minute Rule for Plant Conveyors And Systems

Table of ContentsNot known Facts About Plant Conveyors And SystemsNot known Facts About Plant Conveyors And Systems4 Easy Facts About Plant Conveyors And Systems ShownUnknown Facts About Plant Conveyors And Systems6 Easy Facts About Plant Conveyors And Systems Described

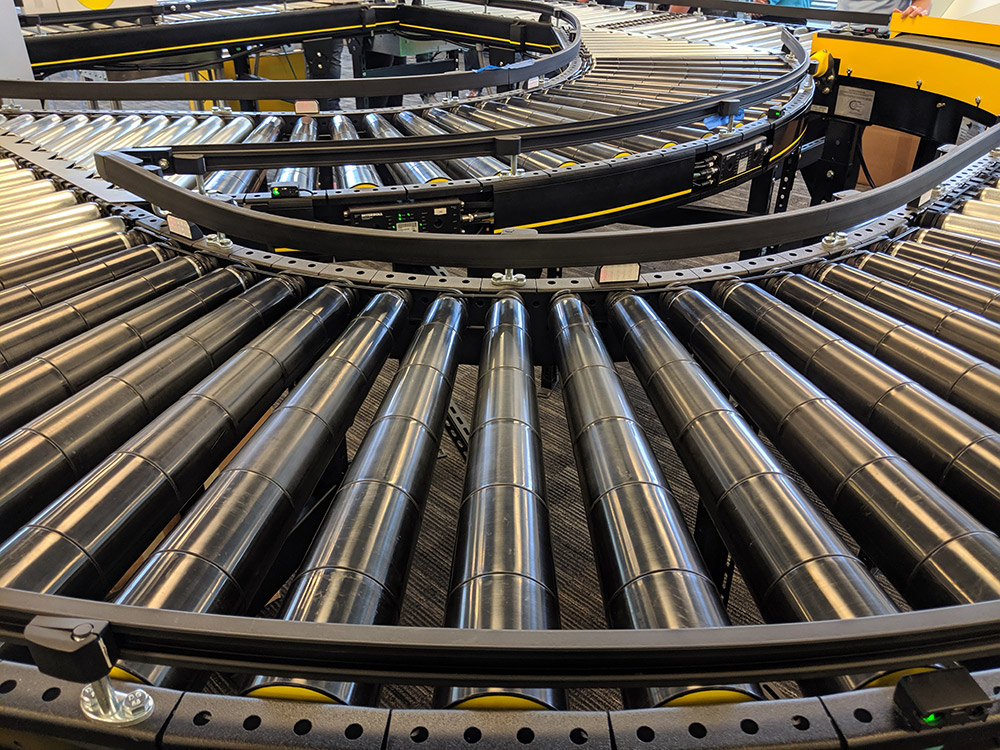

Published On: November 11, 2019 With many different options, it can be hard to know what kind of conveyor systems to make use of in your storehouse automation. Here are 20 usual kinds of conveyors. If you require help choosing systems for your stockroom, get in touch with DCS. This is most likely what you visualize when you consider a conveyor.It is constructed at a mild decrease so components slide downward by themselves. This is like a gravity roller conveyor other than a chain or belt is utilized to make the rollers switch on their very own, so they don't have actually to be developed on a decline. In some cases they can even rise.

Pail conveyor systems are used to move product up and down, by scooping it with a series of pails connected to a belt, chain, or cable television. Basically, picture rows of metal spheres on a table that can transform and also rotate in any type of direction.

Unknown Facts About Plant Conveyors And Systems

As Ultimation clarifies, "A slat conveyor is basically a two-strand chain conveyor with slats attached to the chain and also a guiding system for the slats. This produces a smooth surface area to which tooling information or fixtures can be installed to hold parts in the wanted placement." Below is a video clip of one working. Rather of having rollers or a belt, they have moving chains to lug items. They are generally low to the ground as well as are made use of to lug larger products. See one working. Plant Conveyors and Systems. There is an entire household of conveyors that lug their lots beneath them rather than in addition to them.

Occasionally, as with the Power-and-Free Conveyor, they have two tracksone mechanized and one not motorized. Transform a trolley conveyor upside down, affix it to the flooring instead of the ceiling, as well as you have actually got an inverted monorail. This conveyor vibrates somewhat to move mass material along it.

Plant Conveyors And Systems Fundamentals Explained

There are likewise various other related devices that use a chain to drag things such as a tubular drag conveyor. As NC State College describes, "Sortation conveyors are utilized for combining, recognizing, inducting, and also dividing items to be communicated to details destinations." They use various techniques to sort incoming packages. These conveyors make use of a vacuum cleaner or atmospheric pressure to relocate material.

These are similar to a roller conveyor except with small, individual wheels rather of long, cylindrical rollers. Strolling Beam conveyors relocate material incrementally along the conveyor utilizing moving and fixed assistances.

If you need help selecting a conveyor system, allow us understand. We have over 35 years of experience dealing with jobs large (approximately $30 million) and tiny.

The 4-Minute Rule for Plant Conveyors And Systems

Introduction The click here for info total guide to conveyor systems on the net. Conveyor System Needs Types of Conveyor Equipments Exactly How Does a Conveyor System Work?

Load Capacity: Once the system has been set out as well as given a pattern, it has to be determined what will certainly be the amount Bonuses of materials it can carry - Plant Conveyors and Systems. Overloading a system can harm it or trigger it to stop in the middle of its operation. Factors that affect the load capability are total length and also bed width as well as the drive system.

Unknown Facts About Plant Conveyors And Systems

Motion of powdered, granular, and chip type materials can have dust develop up, which is considered in system style and also might demand some form of filtration. Just like other sharing systems, a cautious evaluation of the features of the product is called for. Setup: Sharing systems can be found in a broad variety of shapes, designs, dimensions, and also forms.

Because each system is made to fit an unique application, it would be difficult to cover all of the various arrangements. What is crucial to comprehend is that there are very few limitations on including a communicating system, despite the application. Drive System: The drive of an automated conveying system is the power that relocates materials.